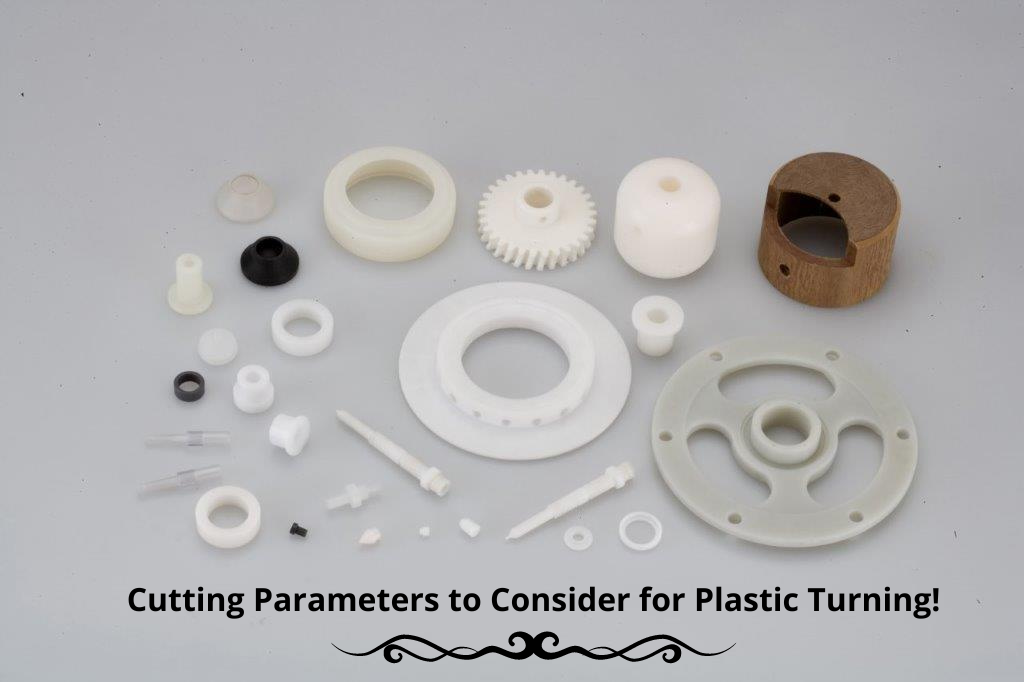

There has been a huge demand for machined quality plastic parts from OEMs across industries to assemble the final product. While plastic parts fabrication has been in practice since decades, CNC machining is the most preferred technique to achieve quality plastic components. There are various machining techniques used as per application requirements. Plastic turning is one of the commonly used methods to achieve the required shape by removing unwanted material from the workpiece. Over the last few years, the demand for machined or CNC turned plastic parts or components has surged, and this has driven the demand for CNC turned superior quality parts. However, there are certain cutting parameters one must consider for CNC turning, and this post discusses the same.

Why CNC Machining?

Over the last few decades, CNC machining has evolved owing to advancements in electronics and its implementation in machining techniques such as turning, milling, and so on. This has hugely improved the speed, efficiency, performance, precision, and accuracy of these machines as well as the capabilities such as multitasking and catering to high volume production runs. Hence, CNC plastic machining is one of the popular machining techniques that has effectively progressed with time and technological advancements. It’s been widely preferred for producing quality plastic parts with tight tolerances. This machining technique is fully or partially automated, and hence demands less human intervention.

A Brief Overview of Plastic Turning

Plastic turning is well-known for the accuracy and precision of dimensions. All turning operations can be performed using a lathe. A lathe is a machine that rotates a workpiece, and a stationary cutting tool is used to cut, remove, and shape the piece in the desired pattern. The cutting tool can only move in a vertical and horizontal motion. Unlike milling, a lathe is popularly called turning equipment that can produce concentrical shapes and identical surface finishes. Below mentioned are some standard rules for plastic turning:

- Single point cutting tool guarantees good turning and polished plastic finishes, which help reduce unwanted material buildups and frictions.

- Feed rates should be 0.004-0.010”/rev. It is dependent on the flexibility of the plastic type.

- Make sure the stationary cutting tool is sharp enough to cut the workpiece in the desired form. Try to insert the width of the tool at a smaller diameter than the minimum diameter of the components.

Determining Cutting Parameters for Plastic Turning

Appropriate cutting parameters are of utmost importance to produce precise plastic parts. They not only help in reducing the machining costs and wastage but cycle times too. The motion and speed of the cutting tool are specified using various parameters. These parameters can be modified depending on the type of workpiece required and the tool size.

- The first and foremost important parameter is the cutting speed. The term measures the number of feet the cutting tool completes over the workpiece’s surface per minute. Simply put, the cutting speed mainly depends on the process and the type of material used.

- Cutting feed is another important aspect for consideration. It is measured in inches per revolution. Cutting feed calculates the distance undertaken by the tool for one revolution. Based on the operation type, the workpiece is fed into the tool or vice versa.

- Next is spindle speed. It is defined as the continuous rotating speed of the tool in the revolutions per minute or RPM. The speed of the spindle varies based on several factors, such as the diameter of the cut or the surface area.

- One should also consider the axial and radial depth of the cut. As the name implies, the axial depth of the cut measures the tool’s depth as it cuts towards the axis of the material. A large axial depth is recommended in case of a high load on the cutting tool. The radial depth of the cut measures the tool’s depth as it cuts along the radius of the material. A lower feed is required to enhance the quality of the cutting tool.

Now, you may have got an idea about CNC plastic turning and cutting parameters. Owing to its beneficial features, this machining technique is widely used across industries. If you require quality plastic parts for your upcoming product or application, you must partner with an experienced industry player in machining and fabrication. Princeton Industrial Products Inc. is a reliable, trustworthy and an ISO-certified industry player specializing in machining quality plastic components or parts that cater to your requirements. Using quality and performance-driven plastic turning machines, they produce complex, high-quality plastic parts or components holding extremely tight tolerances.