High-Precision CNC Swiss Machining

Expert Swiss Machined Parts from Princeton Industrial Products

Precision-designed Swiss machining parts are our specialty at Princeton Industrial Products. We have been machining and supplying intricate parts for mission-critical and tactical applications across industries for several years now. Our advanced CNC Swiss machines allow us to achieve high precision in machining intricate and complex parts. Over the years, we have invested in technology and resources, which gives us a competitive edge and helps us serve our clients beyond their expectations.

Our CNC Swiss Machining Capabilities

We believe that the following CNC Swiss machining capabilities we have developed over the years help us serve our clients better.

Tolerances

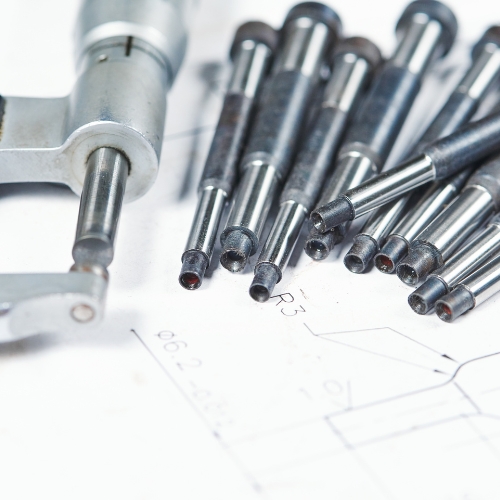

.0002" with a 32 micro-inch finish or better

Machinery Axis

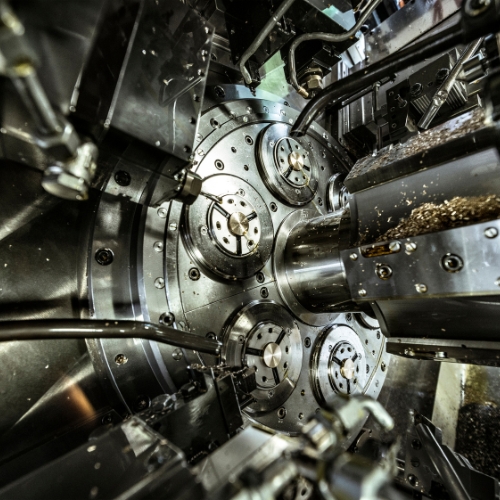

We have invested in multi-axis CNC Swiss machines that help produce precision parts with strict tolerances and complex geometries.

Production Volume

We specialize in everything from prototype to high-volume production. Whether it is one piece or a million, we can produce them with equal ease, irrespective of their application, use, and complexity.

Materials

We regularly work with the following types of metals:

- Aluminum, Brass, Bronze, Carbon Steel, Cold Rolled Steel, Steel, Stainless Steel

- Inconel, Monel, Hastelloy, Molybdenum

Quality Assurance

At Princeton, we are known for delivering quality parts to our customers. Our customers approach us for complex projects because we understand their requirements and prioritize their needs before anything else. Our integrated quality management system is certified to the following:

- MIL-I-45208A (Military Specification Inspection System)

- ISO 9001:2015

- JIT – Just in Time

- KAN BAN

- LEAN

- ESI

Part Dimensions

We can produce parts with 0.125 inch – 1.25 inch part diameters, a minimum dimension of 0.01 inch and a maximum of 36 inches.

File Formats

We accept design files in various formats including SolidWorks, DXF, MasterCam, and PDF.

Additional Machining Capabilities

Conventional Machining

- Turning

- Milling

- Grinding

- Drilling

- Tapping

Industries We Serve

We proudly serve a diverse range of industries, including:

- Electronics

- Construction Equipment

- Military

- Telecommunications

- Medical Parts

- Computer Equipment

- Optical

- Pneumatics

- Off-Highway Vehicles

- Defense

- Recreational and Off-Road Vehicles

- Aerospace

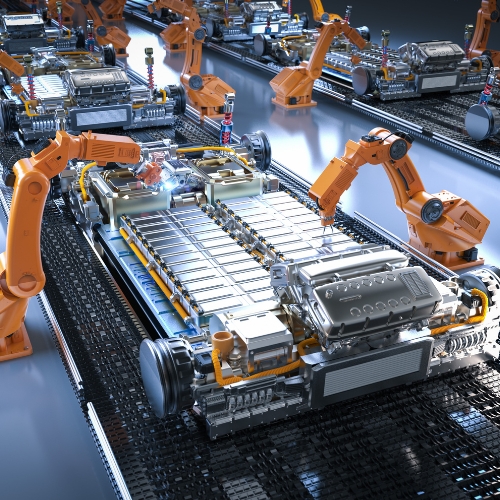

- Automotive

- Hydraulic

An Overview of CNC Swiss Machining

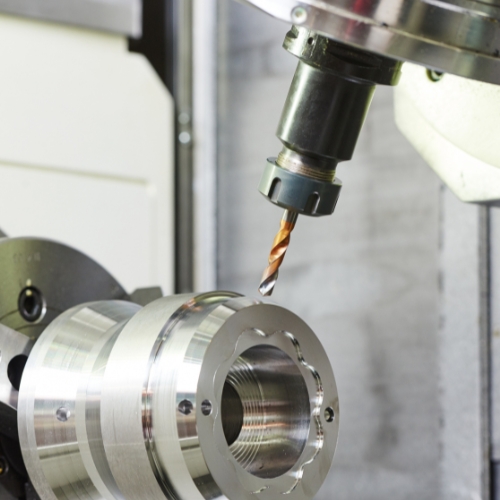

A rod or bar stock, which is the raw material, is fed into the CNC machine. The headstock is clamped on this raw material to be machined. Next, the material is spun and slid by the headstock into the tool zone, where cutting takes place. Some projects may utilize multiple cutting tools in a single cycle, enabling the production of complex components.

Benefits of CNC Swiss Screw Machining Services

The following benefits of CNC Swiss screw machining services make them popular over other services:

High Precision

Swiss screw machines can produce parts with intricacies and complexities that are difficult to achieve with traditional machining.

Versatility

These machines can accommodate a wide range of cutting tools, which perform different machining operations and help us create screw machined parts with different elements. We can also create parts that require critical straightness.

Material Variety

Our CNC Swiss screw machines can accommodate a wide range of materials including regular commercial metals, special metals, and non-metals. This allows our clients to choose the material that meets their requirements.

Tight Tolerances

CNC machining technology allows us to achieve tight tolerances, improve precision, and minimize errors.

Accuracy

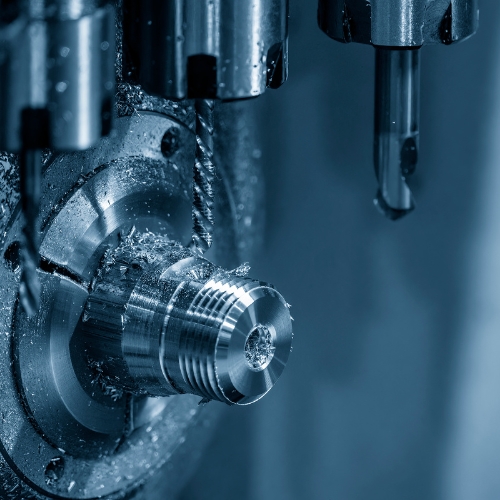

CNC Swiss screw machining assures a high level of accuracy. The distance between the cutting tool and workpiece is minimal, which helps minimize the deflection of the cutting surface and produce parts with tight tolerances and high-quality finishes.

Efficiency

A CNC Swiss screw machine requires minimal intervention and can be operated for a long time.

High Production Rates

The high precision assured by these machines enables us to create Swiss-machined parts in large quantities. Most times, these parts require no secondary finishing.