Precision Medical CNC Machining

Your Trusted Partner for Medical Parts Precision Machining

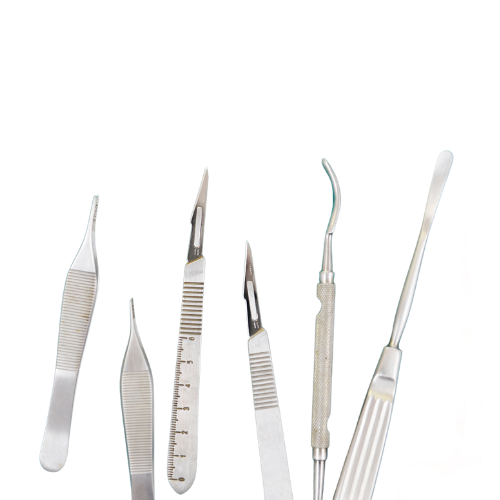

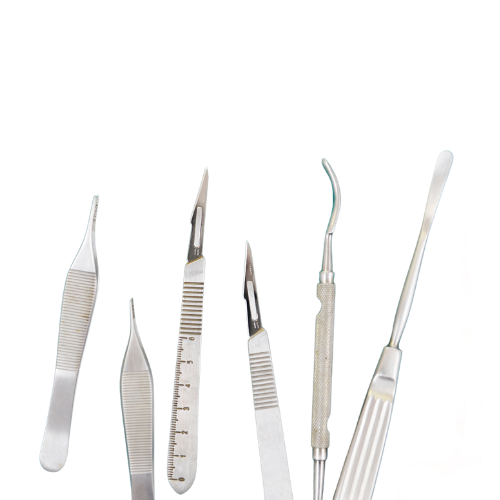

The demand for precision machined parts is on the rise when it comes to the medical industry. They are crucial components of surgical instruments and various other medical devices. As the need for more complex medical equipment continues to grow, medical device manufacturers continue to turn to precision machining for their components. If you are looking for medical parts precision machining services, look no further than Princeton Industrial Products. Our company has been providing instrument machining services to medical facilities for the last 35 years. At Princeton, we have the experience and expertise in creating highly accurate, durable precision machined medical parts that sustain long-term performance. We ensure the right tooling so that the medical devices last longer, translating to better efficiency for healthcare providers.

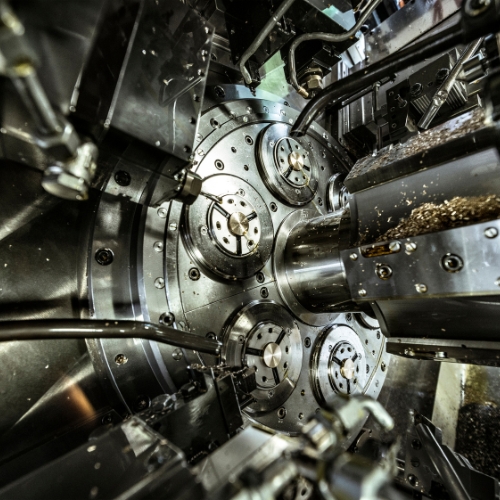

Medical CNC Machining Capabilities

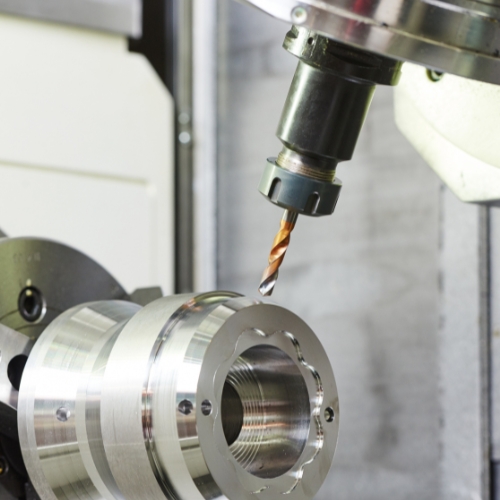

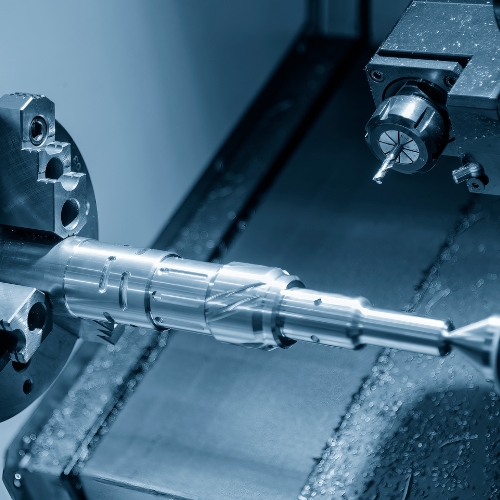

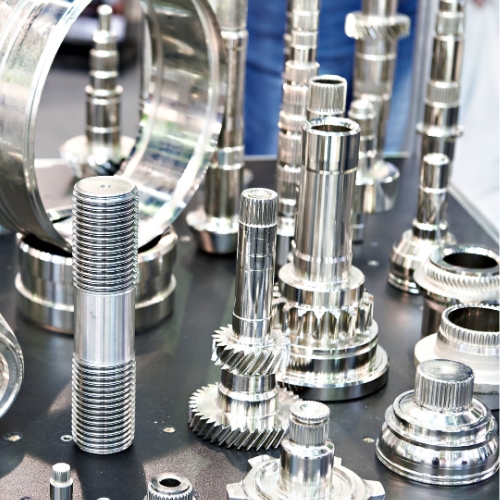

The field of medicine is advancing by leaps and bounds. The increasing use of electronics, lasers, and robotics in surgery has led to a huge demand for precision-machined parts. Medical equipment like radiation therapy machines, surgical robots, and bone saws are highly complex systems that need a high level of accuracy to ensure the safety of patients. The following are our capabilities in precision-machined medical parts manufacturing.

Common Materials Used for Medical CNC Machining

At Princeton, we work with a wide range of metals including:

- Aluminum

- Brass

- Bronze

- Carbon Steel

- Cold Rolled Steel

- Steel

- Stainless Steel

- Hastelloy

- Inconel

- Monel

- Molybdenum

We also work with plastics such as:

- Delrin

- Nylon

- Polyethylene

- Teflon

Quality Assurance

Quality assurance is an essential part of any production process, especially when it involves medical industry machining. We adhere to:

- JIT – Just in Time

- ISO 9001:2015

- KAN BAN

- LEAN

- ESI

These standards help us verify that our products or services conform to the finest quality. We can provide material certifications, process and material lot traceability, inspection reports, dimensional reports, hardware certifications, and more.

Why Partner with Princeton Industrial Products, Inc. for Medical CNC Machining

We have a team of highly experienced professionals who machine workpieces with precision and accuracy. They have immense experience in working with CNC machines, milling machines, lathes, and more. Our machinists are fully aware of the properties and terms of different workpieces they work with

Customized Solutions

We take the time to understand your unique needs, ensuring the final product aligns perfectly with your requirements.

Experienced Team

With over 35 years of industry experience, our team handles even the most challenging projects with precision and expertise.

Advanced Technology

Utilizing the latest machinery and equipment, we guarantee accuracy and precision in every job we undertake.

Commitment to Quality

Our robust quality management system ensures all parts meet the highest industry standards.

Secondary CNC Machine Capabilities

We possess a wide range of secondary machining capabilities that can meet the specific applications of each customer. We have invested in technologies such as:

Plating

This is a method in which a thin layer of metal such as copper, silver, nickel, chromium, and so on is applied onto the substrate. This not only improves the aesthetics but also offers corrosion resistance.

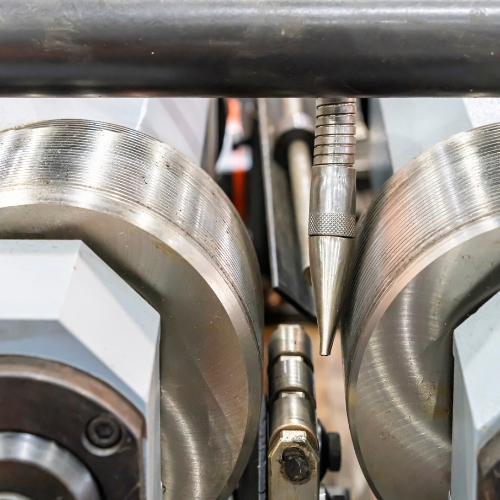

Grinding

This process removes the uneven and coarse particles and materials on the surface of the workpiece. It is done for fine-tuning and smooth surface finishing.

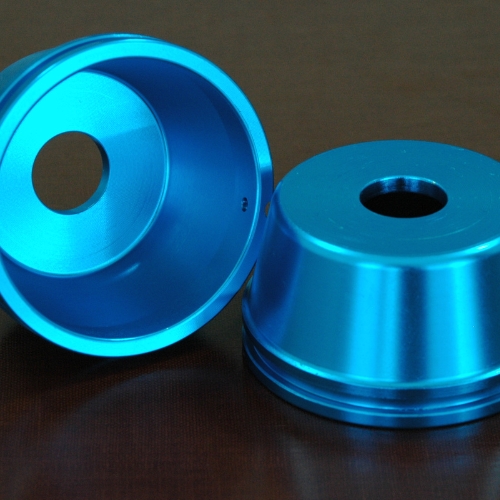

Anodizing

This is a process to lay a thick oxide coating onto the workpiece surface. This makes the surface wear and corrosion resistant as well as improves aesthetics.

Part Identification

Our advanced machines such as the milling and turning centers have the part marking program, which can be programmed to print part markings on the part or product surface.

Heat Treating

Machined parts or components are heat-treated either before or after the machining process. This is basically done to enhance their structural stability, strength, hardness, and other physical properties.

Polishing

The workpiece surface is polished after the machining process to remove coarse materials and burring marks.

Casting Machining

Casting eases the process of a metal sheet being formed into a part or product with tight tolerances ranging in a few microns. While metal casting has been used for centuries, this is now a technologically automated process. It reduces the need to join too many parts, which in turn reduces resources and costs.

Thread Rolling

In this process, metal is rolled through dies to develop threads around the surface, as in screws and other fitting components.

Identification Stamping

In this process, letters of the logo or brand name product name are stamped into the metal workpiece. This is done by embossing, coining, punching, and so on.

Laser Etching

Here, heat is generated onto the workpiece surface by focusing a laser beam, and layers from the surface are removed. The surface thus melts, and permanent marks are created onto it.

Medical CNC Machining Applications

Precision machining is essential for the medical industry as it ensures that surgical, dental, and other medical instruments are made correctly with tight tolerances. Precision parts are used in all types of medical equipment, including CT scanners, X-ray machines, and respirators. They are also used in orthopedic implants like hip replacements and knee implants. Our precision machined medical parts are regularly used in the following sectors:

- Medical Device Manufacturers

- Life Sciences

- Biotechnology Corporations

- Pharmaceutical Companies

- Diagnostics Equipment Manufacturers

- Medical Instrument Manufacturers

A major part of the medical equipment used in hospitals, dental offices, and veterinary clinics is equipped with precision-machined parts. Such instruments machining typically requires high-quality CNC machining machines, CNC lathes, and other specialized equipment. This is why several sectors in the medical industry rely on us for their machining needs, as we own both the expertise and experience in meeting requirements, no matter how challenging they are.