Precision Aerospace CNC Machining

Trusted Partner for High-Quality Aerospace Machined Parts

The aerospace industry is one of the fastest-growing and most rapidly evolving industries in the world. Today, it is worth over $800 billion. Increasing focus on innovative designs, safety features, and fuel economy brings several challenges to manufacturers. Over the years, several manufacturing techniques have evolved across the world. Aerospace CNC machining is one of them. It is employed for building several critical components in this industry. Even a small manufacturing error or imperfection can lead to disastrous results, which is why many original equipment manufacturers (OEMs) rely on this precise machining technique.

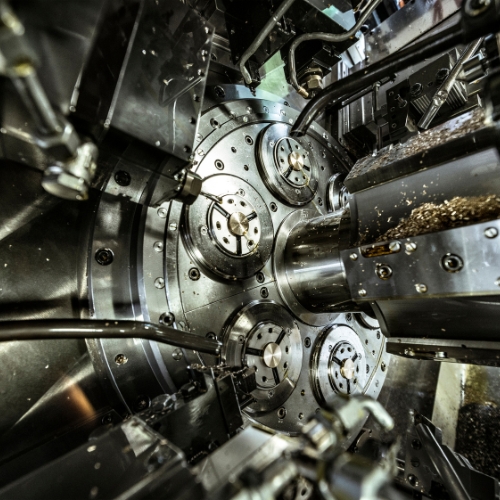

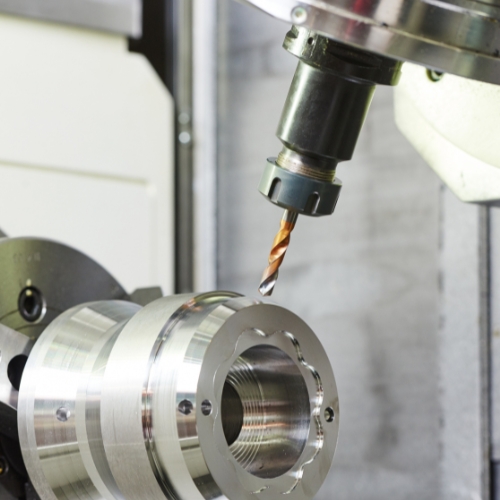

Aerospace CNC Machining Capabilities

Our following CNC machining capabilities have helped us serve our clients efficiently over the years:

Common Materials Used for Aerospace Machined Parts

At Princeton Industrial, we work with the following materials to create aerospace machined parts.

Aluminum

Lightweight, strength, and durability are general requirements for aerospace machined parts. All these requirements are perfectly met by aluminum. It is one of the strongest materials on the earth. The strength and hardness of this material vary according to its alloys. The following are a few common alloys of this material:

Aluminum Alloy Series 6xxx:

Alloys in this series feature silicon and magnesium and offer excellent corrosion resistance, formability, and medium strength.

Aluminum Alloy Series 2xxx:

The aluminum alloy in this series features copper and possesses high strength and durability. The alloy assures excellent machinability and possesses a good strength-to-weight ratio, and is used for creating fuselage and wing structures.

Aluminum Alloy Series 7xxx:

Alloys in this series comprise zinc, chromium, magnesium, and copper in varying proportions. All these contribute to its excellent durability and strength. Aluminum alloys in the 7xxx series are generally used for manufacturing military aircraft components.

In addition to aluminum, we also work with the following materials to produce different aerospace machined parts:

- Steel

- Carbon Steel

- Stainless Steel

- High-Stress Alloys

Why Partner with Princeton Industrial Products, Inc. for Your Aerospace Machined Parts

Customized Solutions

We take the time to understand your unique needs, ensuring the final product aligns perfectly with your requirements.

Experienced Team

With over 35 years of industry experience, our team handles even the most challenging projects with precision and expertise.

Advanced Technology

Utilizing the latest machinery and equipment, we guarantee accuracy and precision in every job we undertake.

Commitment to Quality

Our robust quality management system ensures all parts meet the highest industry standards.

Aerospace CNC Machining Applications

As one of the leading aerospace machine shops in the US, we have had the privilege of working with several top OEMs in the aerospace industry. The following are a few popular aerospace machined parts that we regularly work upon and deliver:

- Shafts

- Valve Components

- Electrical Connectors

- Castings

- Housings

- Filter Bodies

- Structural Components