Electronics Machining Precision Parts

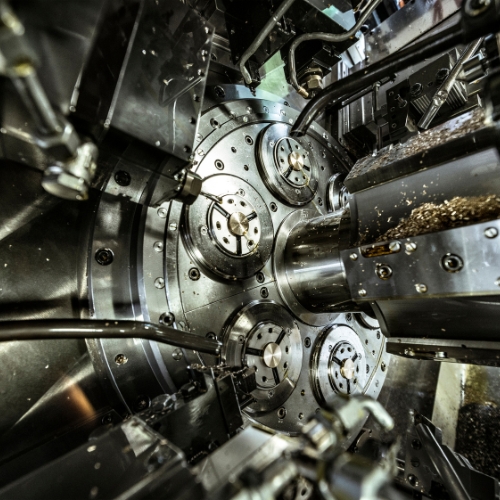

High-Quality CNC Electronics Machining

The electronics industry is one of the fastest-growing sectors globally, featuring products ranging from small electronic components to large appliances. There are active and passive components that contribute to the functioning and performance of electronic equipment. Therefore, they must be designed with precision and care. At Princeton Industrial Products, Inc., we create electronics precision parts using CNC machining. All these years, we have supported our clients in the semiconductor, electronics, and sensor industry segments with our high-quality electronics machining services. Thanks to our advanced CNC machining capabilities and expertise, we can meet all your project requirements with ease. We can produce electronics precision parts with tight tolerances in medium to high volumes.

Electronics Machining Capabilities

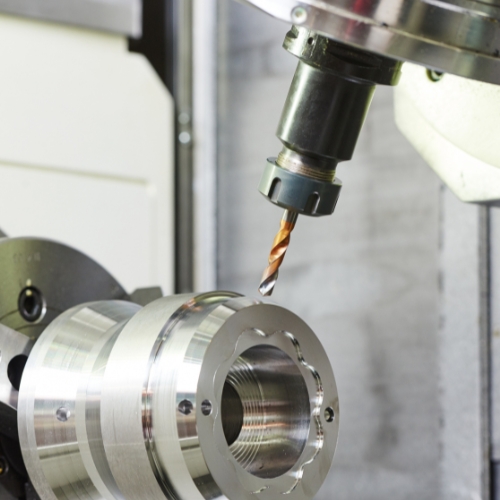

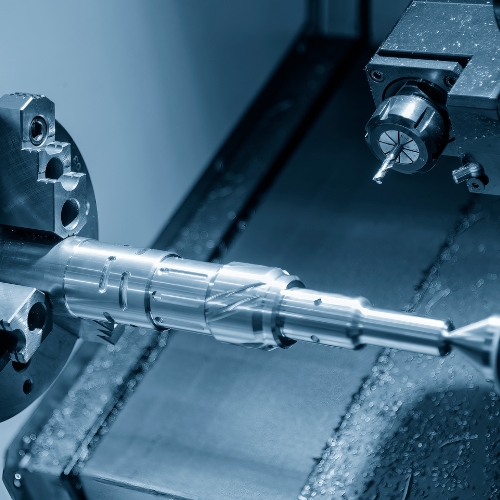

Electronic parts and components have complex details and demand high precision. Our following electronics machining capabilities allow us to meet these requirements with ease.

We provide the following CNC machining services to our clients in the electronics and semiconductor industries:

Common Materials We Work With for Electronics Machining

We work with several metal and plastic materials, including:

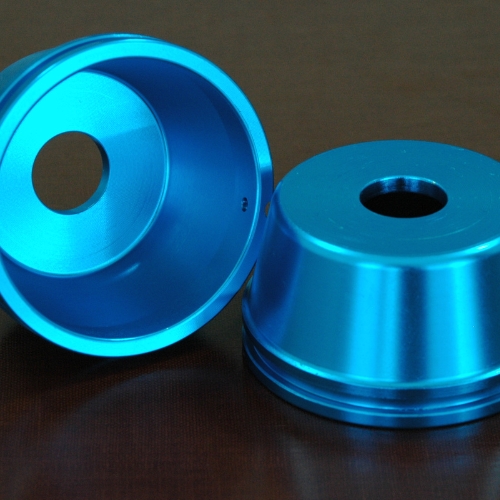

Aluminum

Aluminum is the most economical material for CNC machining. We use this material to create castings for electrical and electronic equipment. Aluminum is known for its excellent strength-to-weight ratio, rust, and corrosion resistance. The parts and components made of this material are chemical-resistant, malleable, and electrically conductive.

Stainless Steel

Stainless steel is known for its corrosion resistance and strength. We work with various types of stainless steel materials, including stainless steel 304, 316, and various alloys. We use stainless steel to create electronic hardware and components that may require corrosion resistance.

Alloy Steel

Alloy steel components are usually preferred in high-stress electronic appliances. We work with a variety of alloy steels, including steel alloy 4140, 41L40, 52100, etc.

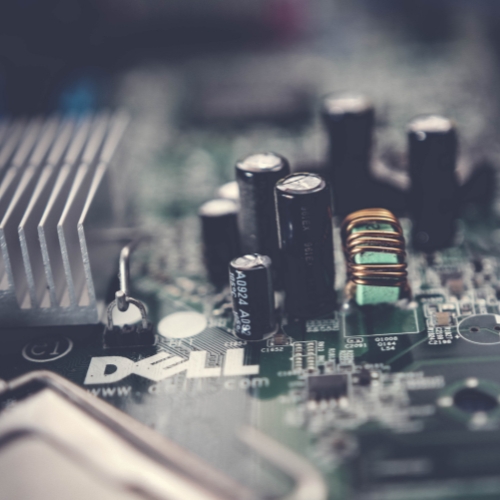

Copper

This material is known for its conductivity, malleability, and reliability. Copper wiring is extensively used in printed circuit boards and motors. We regularly work with this material, which is used in industrial machines.

Brass

This material is widely used in parts that require high chemical, heat, and corrosion resistance. The parts are reliable, durable, and cost-efficient.

PVC

Polyvinylchloride (PVC) is a low-cost plastic that is used for creating parts and components requiring high strength and lightweight properties. PVC parts can be machined to close tolerances and possess excellent flame, water, and corrosion resistance.

Nylon

This is a low-cost plastic that is employed for machining parts that require high friction resistance and compressive strength. We can machine these parts to achieve tight tolerances.

PTFE

This is a resilient material for creating electronic parts that require high durability and strength. The parts made of this material can resist chemicals, radiation, heat, flame, etc. We regularly machine PTFE precision electronic parts for use in moisture-rich environments.

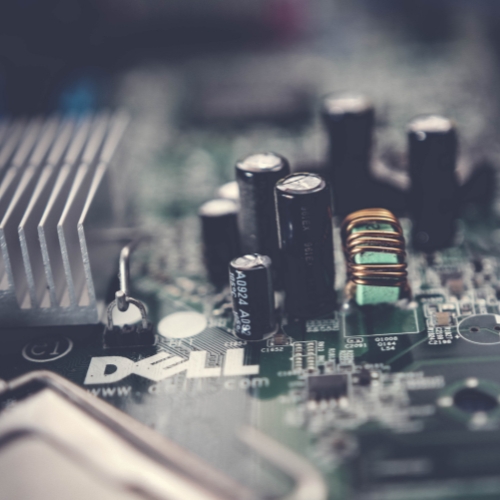

Applications of CNC Electronics Machining

Electronics machining is a challenging sector due to the diversity involved. Each project is unique and often comes with additional requirements. We can fulfill them quite easily and have been successfully delivering on time all these years. The following are some common parts that we regularly machine at our facility:

- Printed Circuit Boards

- Casings and Enclosures

- Heat Sinks

- Semiconductors

- Sockets and Connectors

- Fixtures

- Brackets, Tools, and Chassis

At Princeton Industrial Products, Inc., we are committed to providing high-quality electronics precision parts tailored to your specific requirements. Our team is dedicated to delivering excellence in every project.

Benefits of Partnering with Princeton Industrial Products, Inc. for Electronics Machining

Today, we count many of the top electronics and semiconductor manufacturers among our clients. We believe our advanced machining capabilities and engineering expertise make us a one-stop destination for all your CNC machining needs. The following are a few benefits of partnering with us for all your electronics machining requirements:

Quick Turnaround Times

We can process prototypes and short to medium production runs at quick turnaround times.

Precision Engineering

We understand the level of precision required in some electronics industry segments. Our engineering expertise and technology investments enable us to meet strict tolerances easily, which may be as minute as 0.002mm for miniature electronic devices.

ISO 9001:2015 Certified

We are an ISO 9001:2015 company, and our facilities and engineering practices are testimony to our commitment to quality.

Secondary Machining Capabilities

Some electronic parts and components require excellent surface finishing. The following are some of the secondary services we offer:

Anodizing

This is a process to lay a thick oxide coating onto the workpiece surface. This makes the surface wear and corrosion resistant as well as improves aesthetics.

Heat Treating

Machined parts or components are heat treated either before or after the machining process to enhance structural stability, strength, hardness, and other physical properties.

Electroplating

Electroplating is a process where a thin layer of metal, such as nickel, chrome, or gold, is deposited onto the surface of a workpiece using an electric current. This enhances the part's corrosion resistance, durability, electrical conductivity, and aesthetic appearance.

Passivation

Passivation is a chemical treatment applied to stainless steel and other metals to remove surface contaminants and enhance corrosion resistance. It involves immersing the metal in a mild acid solution to form a protective oxide layer that prevents rust and oxidation.

Powder Coating

Powder coating is a finishing process in which a dry powder, composed of resin and pigment, is electrostatically applied to a metal surface and cured under heat. This creates a hard, durable coating that provides excellent resistance to scratches, corrosion, and fading, while also enhancing the part's appearance.