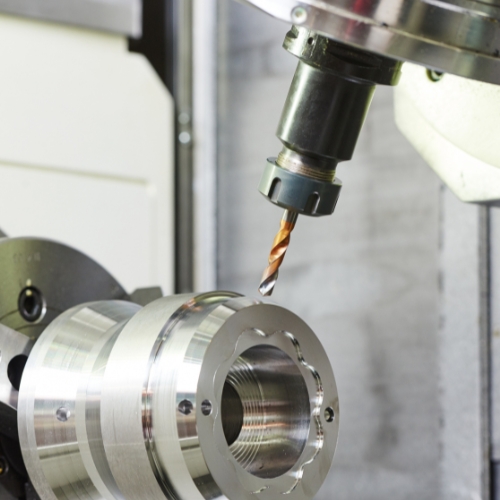

CNC Turning

Precision CNC Turning Services for Complex Parts and Tight Tolerances

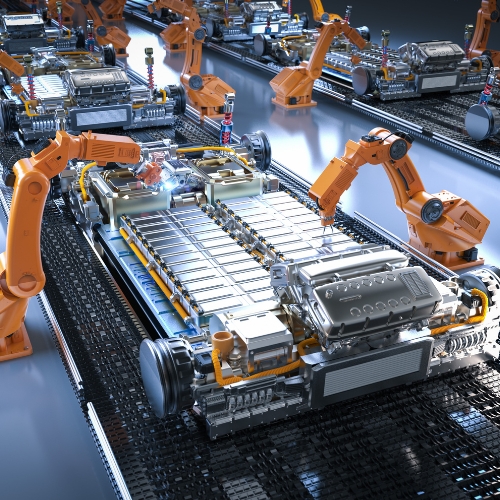

At Princeton Industrial, we specialize in advanced CNC turning services, offering precision machining for both plastic and metal parts. Our state-of-the-art turning centers feature multi-axis machines capable of producing highly complex geometries with exceptional accuracy and quick lead times. Whether your project involves prototypes or high-volume production runs, our CNC turning capabilities ensure efficiency, precision, and timely delivery.

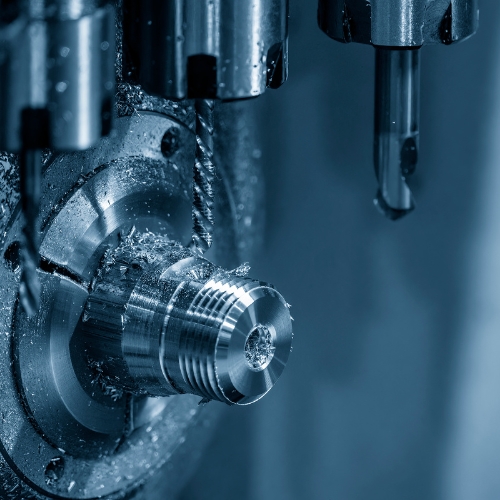

CNC Turning Capabilities

Our CNC turning services stand out for their accuracy and versatility. We utilize advanced equipment to meet a wide range of project requirements

Tight Tolerances

Achieve tolerances as precise as .0002" with a 32 micro-inch finish or better, ensuring high-quality parts for critical applications.

Flexible Volumes

From single prototypes to large-scale production runs, we accommodate your needs with scheduled releases based on product complexity and application.

Quality Assurance

- We follow Lean, JIT (Just in Time), KAN BAN, and ESI systems to maintain high productivity and lower manufacturing costs.

- ISO 9001:2015 certified and compliant with MIL-I-45208A military specifications.

Materials Machined

- Metals: Aluminum, Brass, Bronze, Carbon Steel, Cold Rolled Steel, Steel)

- Exotics: Hastelloy, Inconel, Monel, Molybdenum

- Plastics: Delrin, Nylon, Polyethylene, Teflon

Additional Machining Capabilities

Industries We Serve

We proudly serve a diverse range of industries, including

- Recreational and Off Road Vehicles

- Electronics

- Pneumatics

- Optical

- Military

- Off Highway Vehicles

- Medical Parts

- Automotive

- Computer Equipment

- Construction Equipment

- Defense

- Aerospace

- Hydraulic

- Telecommunications

Why Partner with Princeton Industrial Products, Inc. for Your CNC Turning?

Customized Solutions

We take the time to understand your unique needs, ensuring the final product aligns perfectly with your requirements.

Expert Team

Our skilled machine operators and engineers ensure every project is completed to the highest standards.

Advanced Technology

Multi-axis machines and bar feeds ensure speed and accuracy, combining the efficiency of a screw machine with the precision of CNC turning.

Commitment to Quality

Our ISO 9001:2015 certified facility is equipped with stringent quality checks to guarantee flawless parts.