Manufacturing units of several industries heavily rely on precisely fabricated parts and components to manufacture the final product. Precision machining can be achieved with the help of advanced CNC machines that can make various complex geometric shapes, angles, bends, and so on, keeping precision intact in terms of dimensions, structure, and so on. Also, this is regardless of the volume of parts that need to be produced with equal precision. This may include cutting, forming, milling, and other machining techniques. Precision machining has evolved with time and advancements in technology as these machines are upgraded to cater to the latest requirements in the market. This precise metal machining technique offers unmatched accuracy while catering to small and huge volumes. Are you intrigued to know more about precision machining? Why use precise metal machining? Which are the areas where this precise metal machining is used? This post gives insights into precision machining. So, stay tuned.

A Brief Introduction to Precision Machining

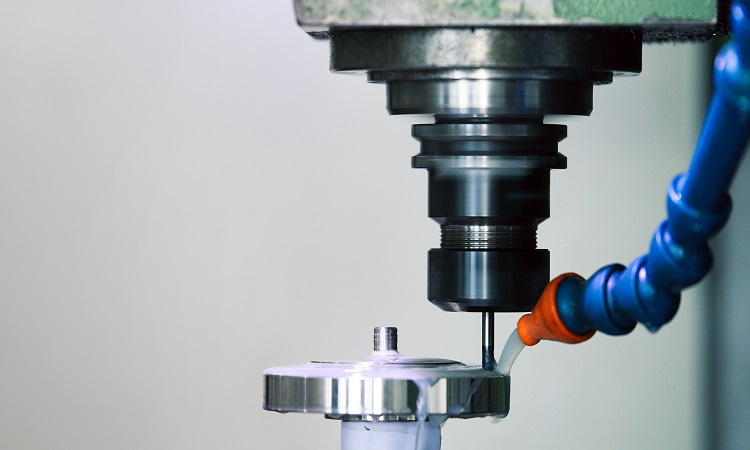

CNC precision machining is an automated or partially automated process used by fabricators or machining service providers. OEMs (original equipment manufacturers) partner with these fabricators to buy precise machined parts and use them to manufacture the final product. In CNC precision machining, all processes are controlled through programming commands, encoded into the system to produce products with the required specifications. Precision machining allows you to carry out different processes on the same machine using multiple axes, such as milling, cutting, forming, drilling, and more. Precision machining has gained immense traction for the capacity to fabricate complex parts, which may not be possible using conventional methods. The following section describes the noticeable benefits of precision machining.

Why is Precision Machining So Popular?

There are several reasons for choosing precision machining over standard machining. Precise metal machining produces parts or components to an exacting standard, and they can repeat the same task thousands of times with equal accuracy. Additionally, it is the best solution to meet the stringent project requirements. The following reasons have immensely contributed to the popularity of precision machined parts. So, let’s have a look at them.

- One of the main reasons behind the popularity of precision machining is the capacity to achieve tight tolerances. Popularly called dimensional accuracy, it is the deviation amount of a specific part that is acceptable by conventional standards. Tolerances are of utmost importance across industries as per their requirements. In the precision machining process, tight tolerances can be achieved while reducing turnaround times and overall production costs. Using the right equipment, this metal machining technique can produce parts with tolerances as tight as ±0.0001.

- The accuracy of precision machining is unmatched and superior to traditional machining techniques. These machines are well-equipped with advanced software and features, which guarantee the accuracy of the machined part. Precision machining also ensures high positional accuracy and a high degree of repeatability.

- OEMs need to deal with diverse materials on a daily basis. This may include a wide range of plastics or metals. Precision machining allows fabricators to cut, shape, and trim materials in the desired shape without compromising quality or efficiency. As the machines can efficiently work with multiple materials, the operator can perform multiple tasks and create different parts simultaneously.

- Similar to any other automated machines, precision machines require less supervision. It means a single operator can oversee different operations of the machines.

- Aluminum

- Copper

- Plastics

- Brass

- Bronze

- Titanium

- Tool steel

- Exotic alloys

- Carbon steel

- Stainless steel

- Aerospace and Defense: Safety and accuracy have always been the top priority in the aerospace and defense industries. Most OEMs emphasize using precise contraptions as small errors can cause damage to several other devices or vehicles. To meet the application demand, OEMs use precise machined parts that guarantee safety and accuracy.

- Automotive: This is a more competitive industry compared to others as several OEMs introduce new vehicles every year. These vehicles demand precise machined parts or components fitted with other accessories to ease different challenges and increase comfort and safety.

- Medical: Precision machining is widely used in the medical industry to meet uncompromising quality and consistency requirements. Machinery used in this industry is complex with no room for even small errors. Additionally, the machined parts must be durable, of smooth finish, and of the highest quality. Precision machining fulfills these requirements as it operates on multiple axes.

- Agriculture: Agriculture is rapidly evolving, thanks to the advanced farm tools and equipment which can cater to ever increasing food demands. For producing farming equipment, OEMs use materials that are light in weight yet durable to improve productivity and user experience. Precision machining is a great option available to fulfill these diverse requirements.

Types of Materials Used for Precision Machining

Here is the list of different materials used for precise metal machining.

Industrial Applications of Precision Machining

Aside from the engineering industry, precision machining has gained immense traction across other sectors owing to its undeniable benefits. Precision machining parts are employed across the following industries:

If you are an OEM specializing in making precise metal or CNC plastic parts, you may require fabrication and precision machining services. Being a reliable, trustworthy, and experienced industry player, Princeton Industrial products, Inc. offers precise plastic and metal machined parts at the most competitive prices.