High-Precision CNC Turning & Milling

CNC Turning

Our state-of-the-art CNC turning centers enable us to manufacture very complex parts with shorter lead times in both production and prototype size lots. Many of these turning centers are equipped with bar feeds, providing the speed of a screw machine with CNC accuracy.

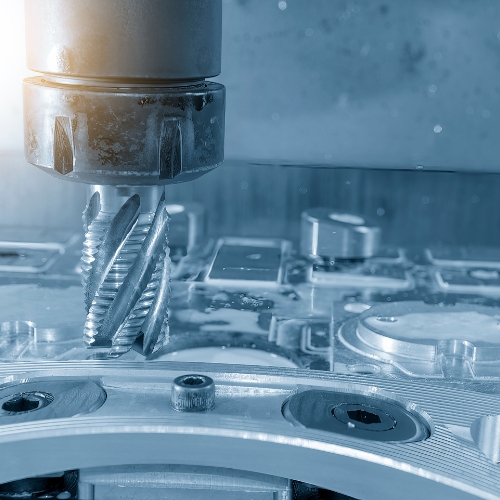

CNC Milling

Our CNC machining centers provide exceptional accuracy for those parts that cannot be turned. These machines can perform many labor-intensive operations with extreme accuracy and consistency, holding tolerances as close as 0.0002″.

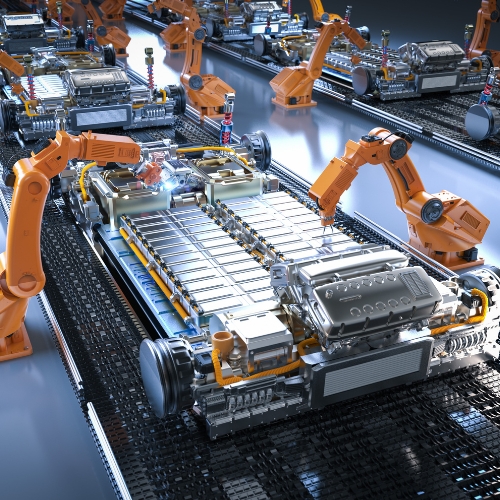

Industries We Serve

We proudly serve a diverse range of industries, including:

- Electronics

- Construction

- Military

- Oil & Gas

- Pharmaceutical

- Sensors

- Trucking/Transportation

- Security & Safety

- Semiconductor

Why Partner with Princeton Industrial Products, Inc. for Your CNC Turning & Milling Needs

Customized Solutions

We take the time to understand your unique needs, ensuring the final product aligns perfectly with your requirements.

Experienced Team

With over 35 years of industry experience, our team handles even the most challenging projects with precision and expertise.

Advanced Technology

Utilizing the latest machinery and equipment, we guarantee accuracy and precision in every job we undertake.

Commitment to Quality

Our robust quality management system ensures all parts meet the highest industry standards.